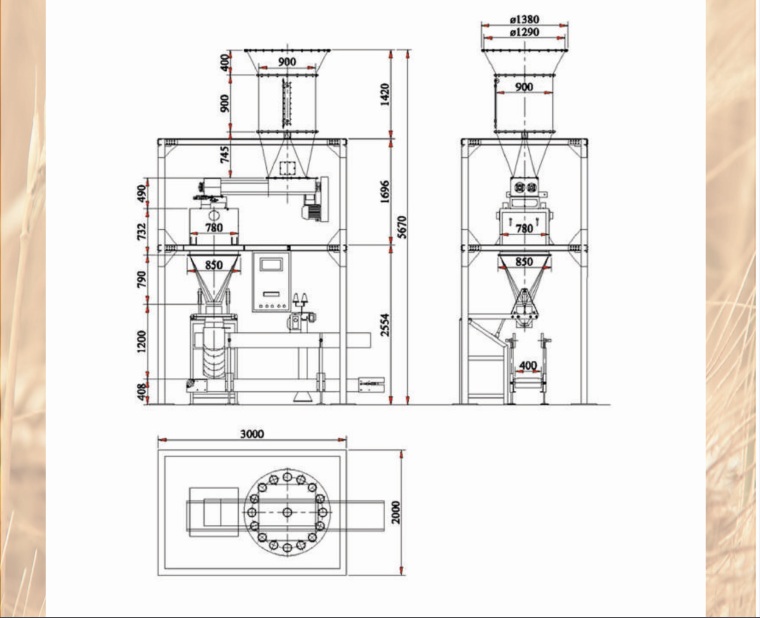

automatic packaging

-FAST - SLOW SPEED: There are two programmable set values in the system. And filling weights belonging to these values can be entered separately. The program setting for the slow cycle is automatically determined and adapted by the system to make the most sensitive and fast weighing. Optimum speed adjustment is made automatically according to the type of flour weighed and the silo level. TOLERANCE: Upper or lower tolerances can be programmed separately. Except for these tolerances as a result of the weighing, flour is not downloaded from the weighing bunker without the operator's knowledge and intervention. BAG SIZE: The recommended bag size for high-capacity bagging is 65 x 95 cm. REQUESTED BAG SIZE: Before starting the bagging process, how many bags are desired to be filled is programmed. The desired number of bags can be changed during bagging. The system can also be stopped before the system reaches the value. Or the desired number can be continued by reprogramming. The number of bags to be bagged left during filling can also be displayed. TOTAL NUMBER OF BAG BAGS: The total number of bags bagged since the reset can be viewed at any time. TOTAL BAG TIME: The total net bagging time since reset can be viewed at any time. UPPER CHAMBER LEVEL CONTROL: The level is automatically controlled by the system with the level sensors in the regulation chamber. ALARMS: Opening and closing errors are reported to the operator by obtaining information from the PLC unit and the mechanical cover and sensors in the system.