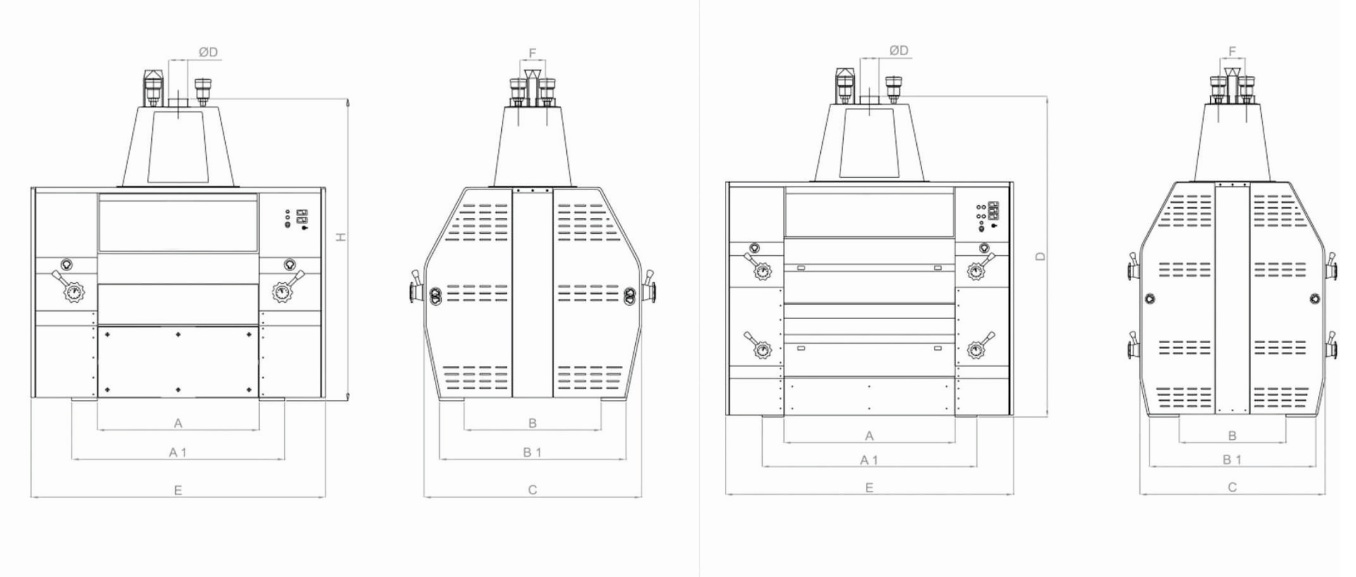

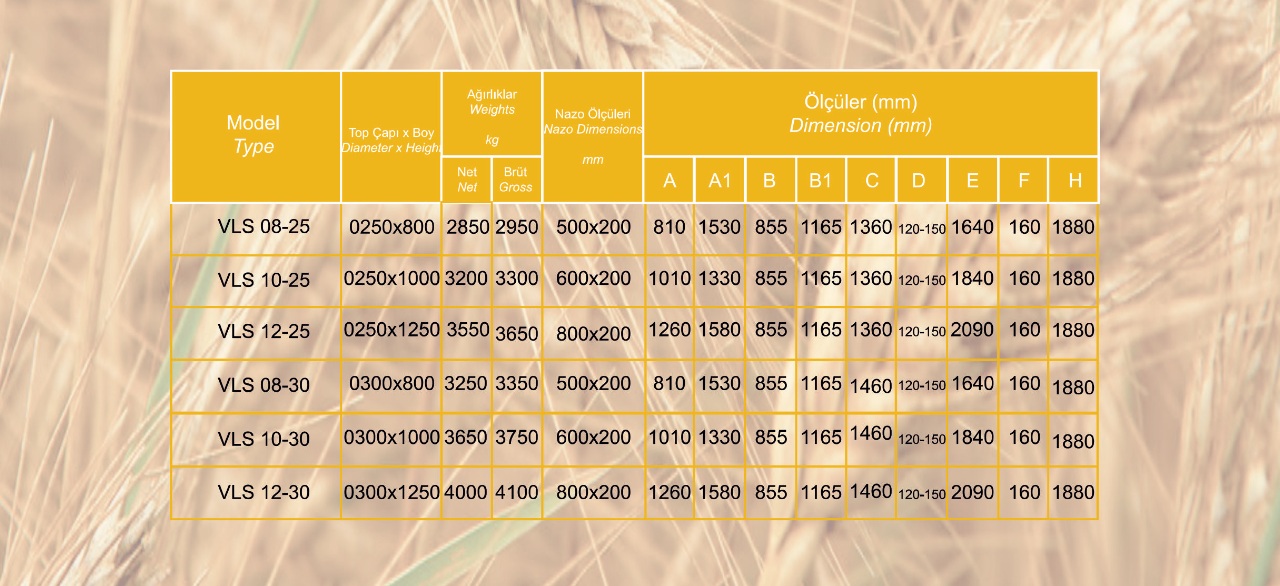

waltz roller mill

It is a machine that works with a full compressed air system, used to turn the wheat coming from the cleaning unit into flour in flour factories. - The chassis is made of sheet metal construction and the lower chassis is completely combed on the borvek bench in order to ensure the parallelism of the balls. - Rubber wicks are placed under the bed skids to absorb vibration. - The properties of the roller balls mounted on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. Features: - All controls on the machine are made with the help of air-activated valves and there is no electricity consumption. - Depending on the amount of incoming product, the valves are stimulated and the pistons are closed and the grain balls are activated. - Thanks to the plate on the grain balls, the amount of product can be adjusted and a curtain flow is provided between the rolls. -The cleaning of the roller balls is done by means of the brushes at the bottom, and the product is prevented from sticking to the ball and plastering. - As soon as the product flow ends, the re-exciter valve is activated and moves the pistons, allowing the balls to be separated and the grains to stop. - Gears that transmit motion are helical and provide high power transmission with little noise and vibration. - The parallelism of the balls can be adjusted precisely from the adjustment levers on the front. - The amperage drawn by the machine during operation can be seen from the ammeter on the panel. - The entrance part of the product to the machine is made of mica material and is transparent so that the product flow can be easily seen.