square sieve

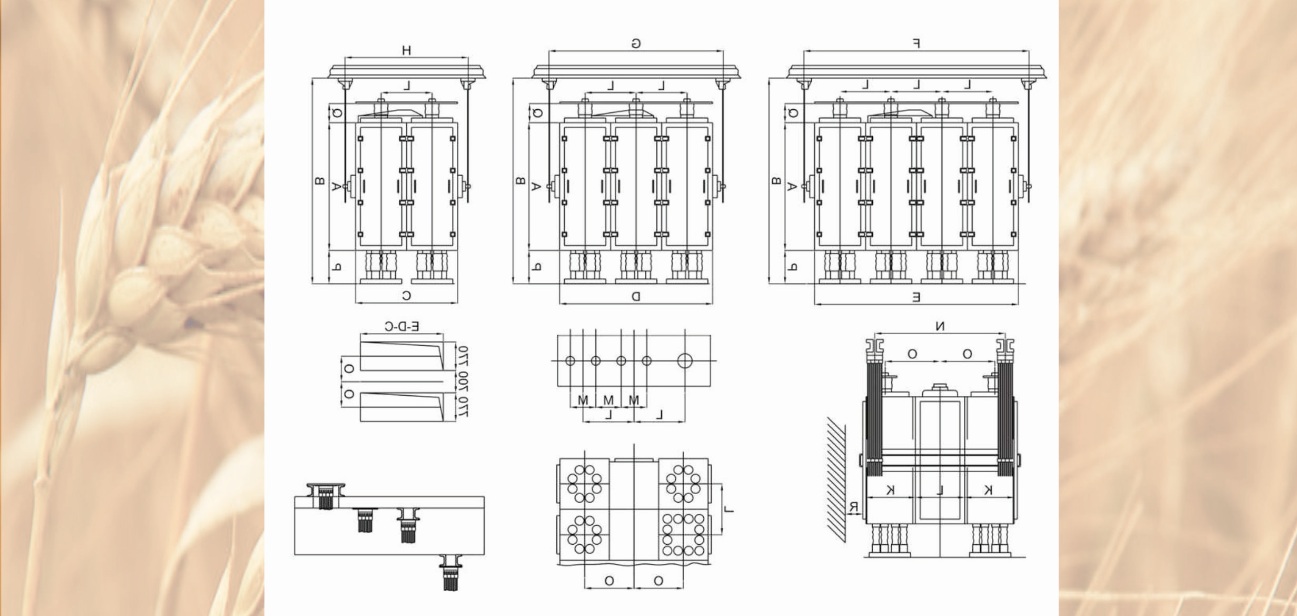

Thanks to the body swinging with free movement and the different sizes of crates in each passage inside the body, it ensures that the grinded product is sorted in a clean and orderly manner. - After being sifted and homogeneously separated, the product in various proportions is automatically directed to the outlet channel through the channels in the frame, the channels between the frames and the channels in the main chassis, and is discharged out of the output pipes with the control pipes. - The surfaces of the cases are covered with formica. The outer covers of the passage are insulated, so the leakage of flour particles is prevented. - The product enters the first box as one or two batches from the entrance section above the passage and flows along the passage height of all the crates. -By placing spacers between the frames of the main frames, the product output volume increases, preventing accumulation and ensuring sufficient product flow. Telora cases in each passage are compressed by the jacks on the outer surface of the sieve. - The sieve outer body is mounted on the factory chassis with suspension rods (flexible). The product inlet is provided from the upper part of the sieve. The product exit part takes place from the lower part of the sieve.