angular forced anneal

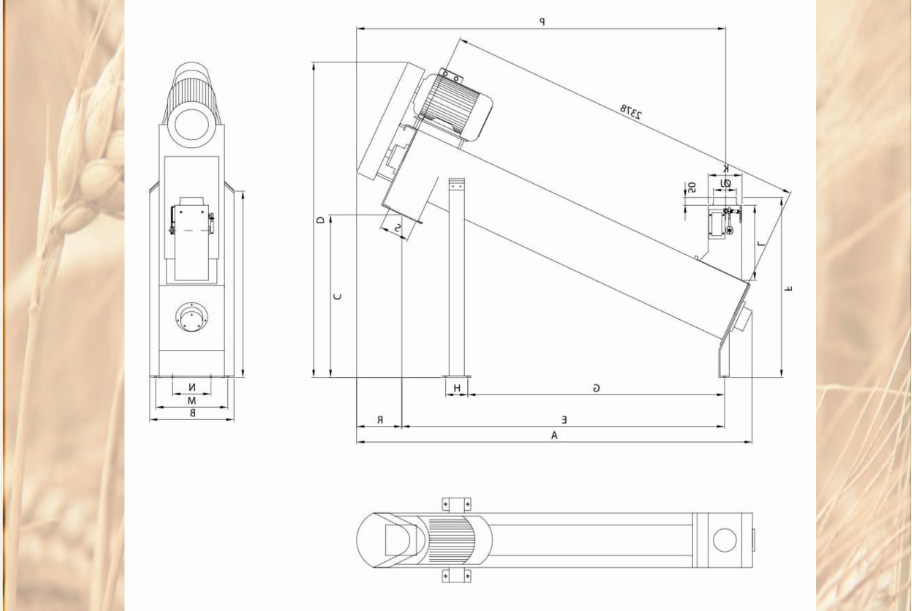

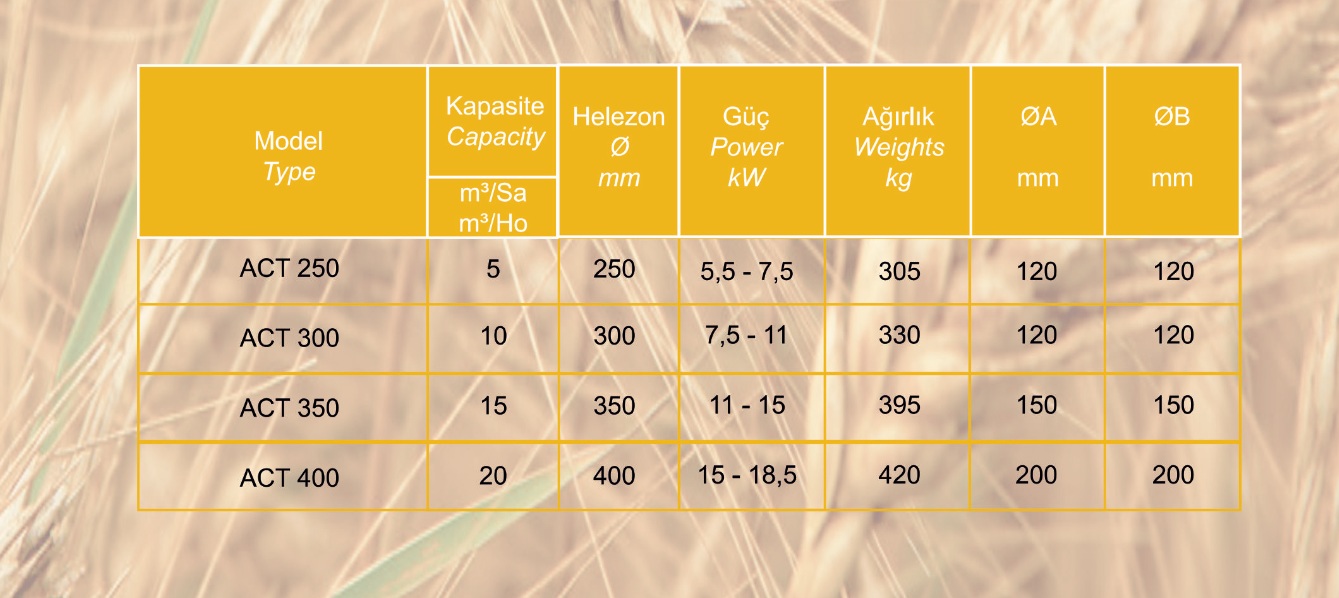

It is designed to provide a high amount of moisture to cereal products. It is generally used in dry cleaning units in flour and semolina factories to provide the desired humidity by giving annealing in a shorter time. In angular forced annealing, the pallets attached to the rotor in a half-moon shape allow the product to be mixed intensively while transporting it. The water to be supplied to the angular forced annealing machine is first cleaned by passing through the filter, and the sensor that detects the flow of wheat gives the pre-set amount of water to the system by opening the solenoid valve, the sensor closes the solenoid valve when the flowing wheat is cut off. Minimum annealing time provides maximum annealing. Made entirely of stainless steel (AISI 304). Different models and engine options are available according to the needs.